Innovative counterattack, technological breakthrough, oil-free vortex

Accumulated product reliability practical testing >80,000 hours

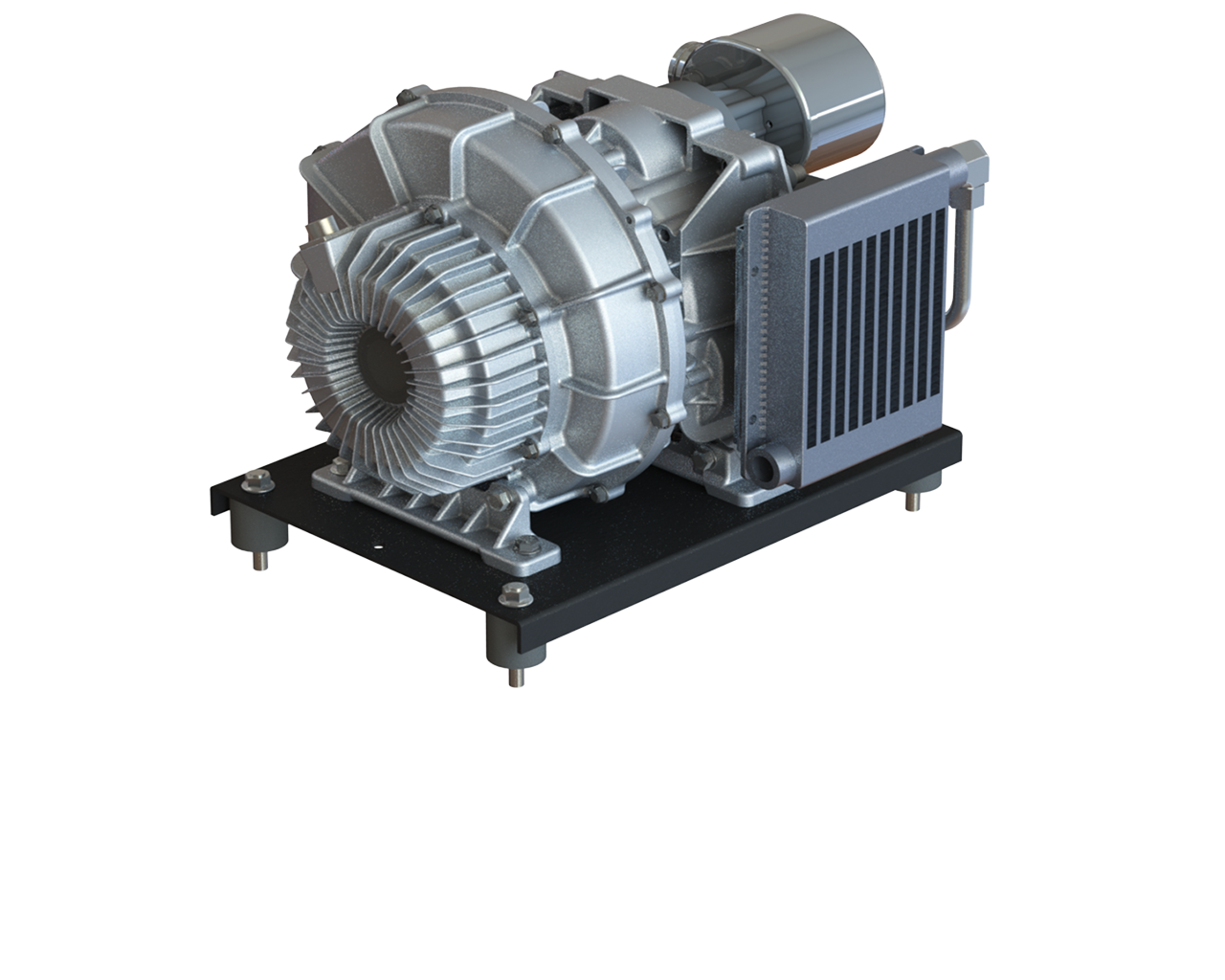

Totally oil-free compression High air quality

There is no oil/carbon pollution in the air, and it has passed oil-free testing and certification

Zero emissions/low power consumption Low cost of use

No waste liquid treatment, energy saving, low consumption and low operating cost

Few parts High reliability

No risk of oil leakage, no need for centralized condensate handling, suitable for harsh environments

Can be used nearby Low noise/low vibration

There is no contact between the moving and static disks during operation, resulting in lower noise, quieter and safer operation

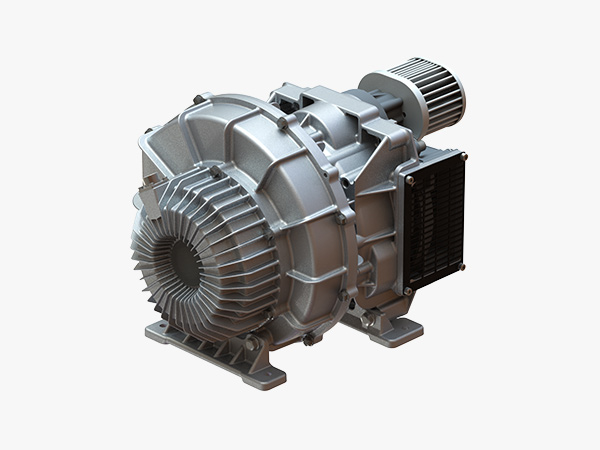

Modular integration Small size/light weight

Quick installation, more convenient to use

No wearing parts Long life and low maintenance

During the entire life cycle, it only takes 1.5 hours per year to perform preventive maintenance and check whether the filter is clogged and clean

High collar vortex technology achievement products

High market share

Comprehensive mastery of vortex R&D and design technology

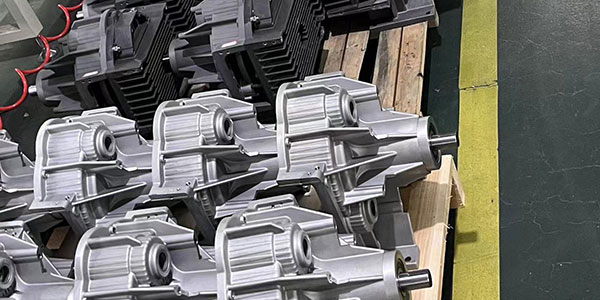

Large-scale production by source manufacturers

——

Semi-automatic assembly line

Semi-automatic assembly line

18 imported CNC machine tools

18 imported CNC machine tools

Possess high-volume quality process control capabilities

Possess high-volume quality process control capabilities

High quality raw materials

High standard testing equipment

Precise production control

Third-party quality inspection report

Special aircraft technology, high-precision OEM customization

Strictly implement ISO9001 and IATF16949 quality systems

Vortex line special machine processing

The high-collar scroll product line tolerance control is ±0.008mm, and the strong single-machine production capacity lays a solid foundation for future industrialization to reduce mass production costs.

Special machining of eccentric shaft

The independently developed eccentric shaft machine and counterweight eccentric shaft machine have eccentricity tolerance control up to ±0.004mm to ensure the performance of the scroll compressor.

Special angular contact bearing production

The high-level team has developed a special angular contact bearing with a special structure for oil-free scroll compressors, with indicators exceeding P4 level and production costs controlled at P5 level, reducing the supporting costs of oil-free scroll compressors.

Design of variable diameter multi-spiral multi-stage scroll compressor

This product adopts a variable diameter multi helix multi-stage design, with a short compression stroke and small lateral internal leakage, while improving energy efficiency.

Integrating research and production to lay the foundation for high quality

Mature application of high-collar oil-free scroll products

Provide you with high-quality oil-free air solutions

News · Encyclopedia · Information

FOCUS ON

MANUFACTURING

GO INTO GAOLING

Focus on oil-free scroll main engine manufacturing

Zhejiang GaoLing New Energy Technology Co., Ltd. was established in 2016. It is a high-tech enterprise specializing in the research and development, manufacturing, sales and service of vortex fluid machinery. It has a factory area of 5,000 square meters and currently has more than 70 employees and 38 professional and technical talents. It is one of the largest oil-free scroll compressor manufacturers in China.

Corporate Style

400-880-5687 / 138 5725 7465

400-880-5687 / 138 5725 7465